What are moulds?

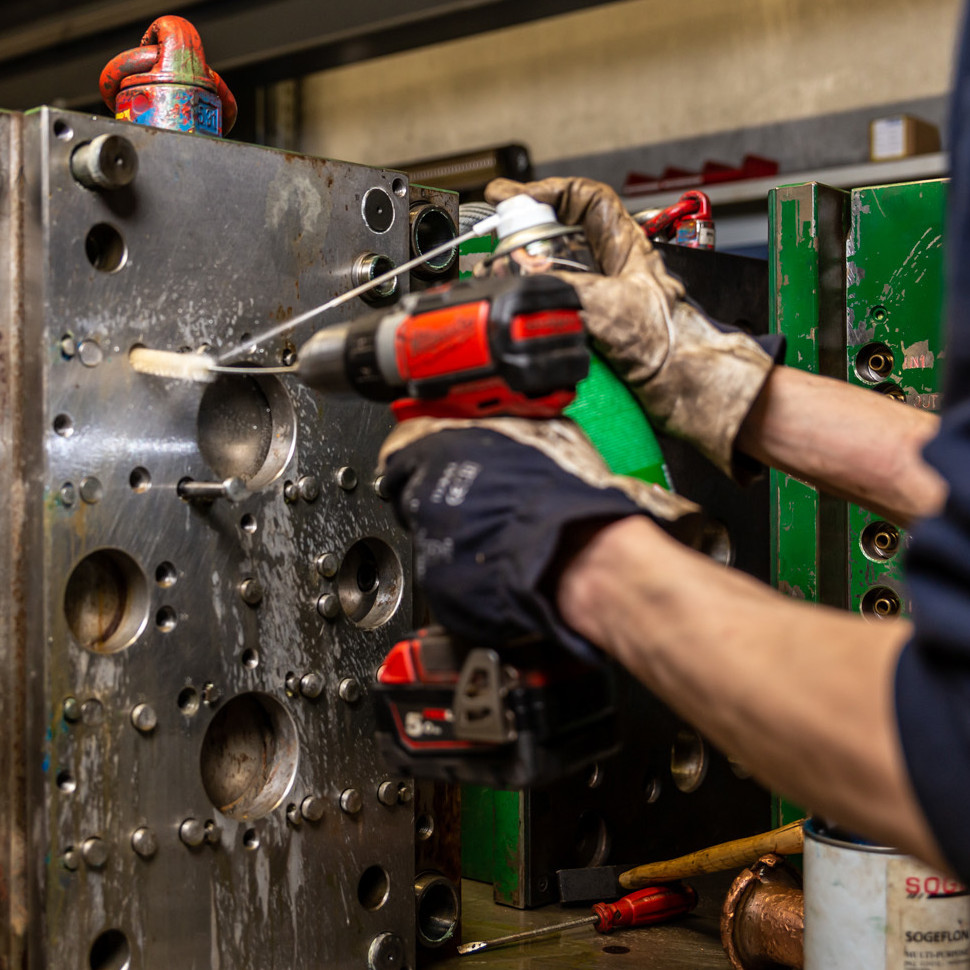

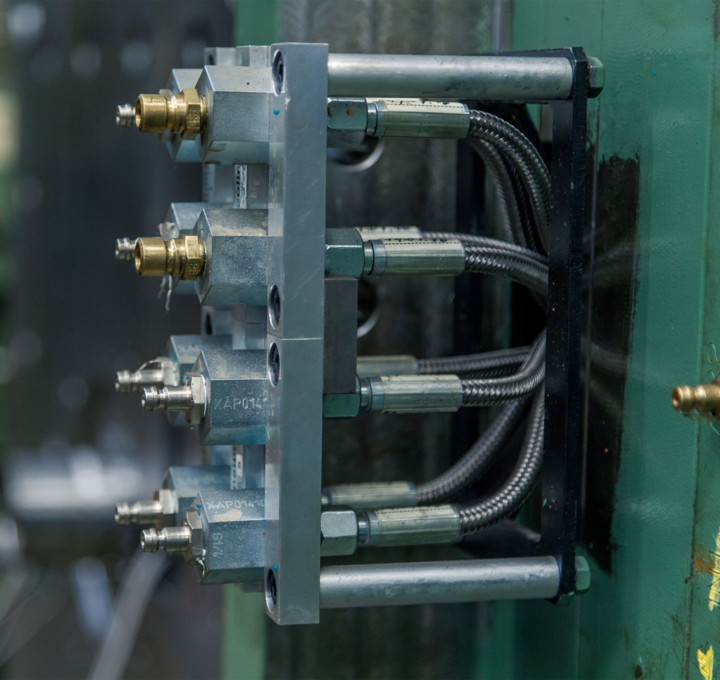

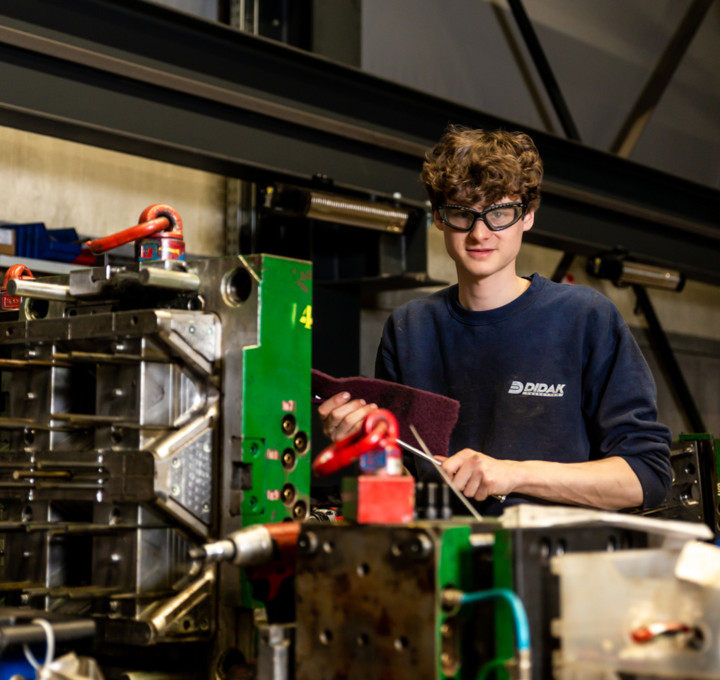

Moulds are carefully crafted steel components used in the plastic injection moulding or custom moulding production process. The most complex shapes or details are possible.

In injection moulding, the plastic is first melted and injected into the mould under high pressure. Once the liquid has cooled evenly, the final product can be removed from the mould.