Expertise from design to production

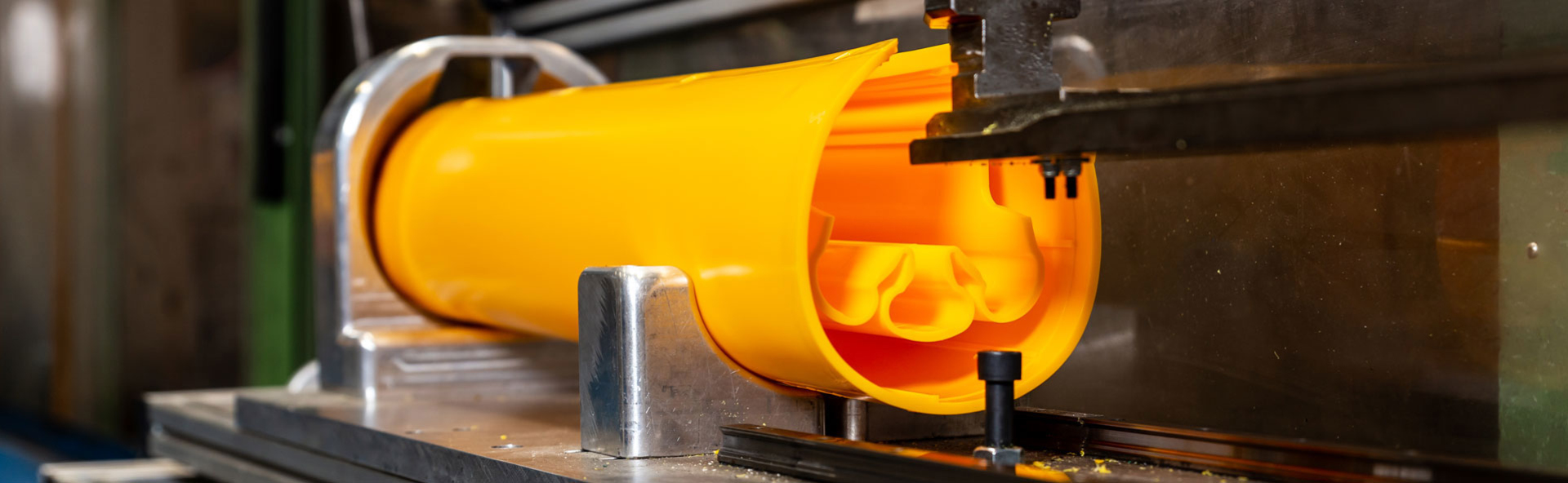

Do you need a specific product, or a product component with specific requirements, such as custom dimensions, shape or material? Are the numbers high enough to justify a mould investment? Then custom moulding can offer the ideal solution.

With custom moulding, custom moulds are made in order to meet your needs for manufacturing a custom product.

It is important for you to involve Didak Injection from the start of your project. This allows us to incorporate points of attention which are useful for the injection moulding process at the start of the design. This can influence the final choice of materials for the design.

Advantages of custom moulding:

- High Accuracy: Use of high-tech machinery

- Fast production time: The injection moulding process has a faster turnaround time since machines are able to produce large numbers

- Durability : The plastic injection moulding process creates less waste than traditional production methods. Moreover, we also work with sustainable and/or recycled materials.